KATŪ300 GKL Welding Carriage Linear Weld Oscillation

KATŪ300 GKL Welding Carriage Linear Weld Oscillation

Mehta Sanghvi & Co is the "Authorised Channel Partner for Gullco International"

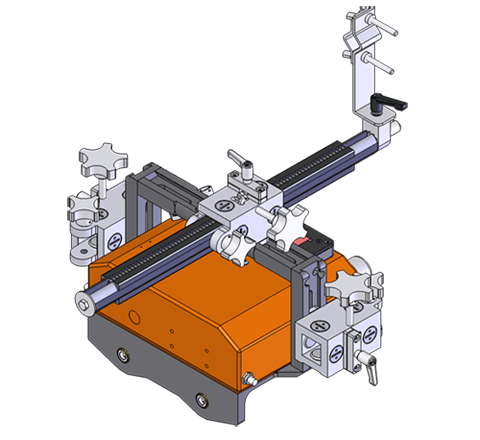

KATŪ 300 WELDING AND CUTTING AUTOMATION carriages are the most long-lasting, highpowered,

and resourceful machines available in the industry. They are sturdy and have been

designed to be compact and light weight than previous models.

Key features include:

1. Tool-less setup

2. Adjustment, and operation

3. Self-aligning wheels

4. Dynamic dovetail racking

5. Quick clutch mechanism

6. Sealed construction

7. Torch holder memory

The Gullco KATŪ300 Weld Oscillation carriages are now re-designed in compact size, are light

weight, robust than previous models as these Weld Oscillation carriages are in much demand

globally.

KATŪ300 Weld Oscillation carriages features:

• Weld Oscillator control provides Auto Arc Start

• Independent dwell at each end and centre of the 1.5" stroke,

• Infinitely variable 0 to 5 seconds.

• Oscillation speed potentiometer,

• Speed range 8 to 188 cycles per minute (16 to 376 passes per minute).

Other engineered features include : Tool-less Setup, Adjustment & Operation

Self-aligning Wheels (Easy Installation) : Self-aligning wheels means the carriage is mounted to

the track correctly and easily every time. This ensures smooth carriage motion and maximizes

the life of the track.

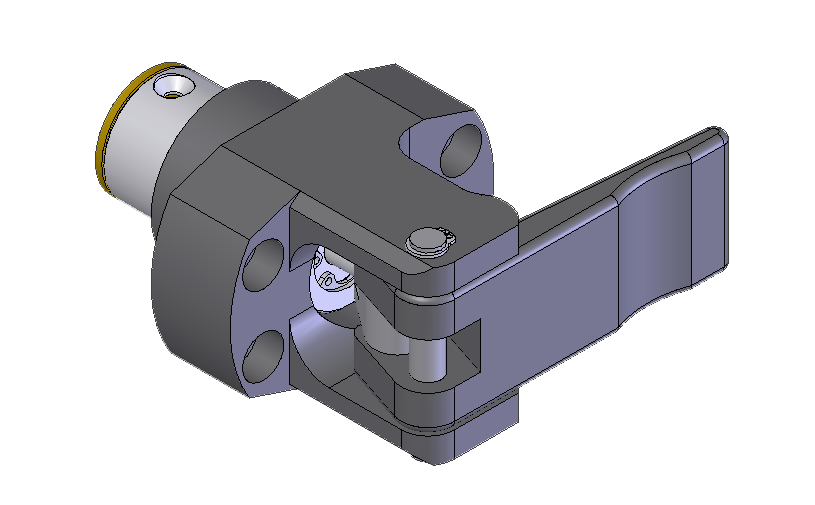

Dynamic Dovetail Racking for versatile torch positioning : Using a machined dovetail racking

system and locking rack box, torch positioning is versatile and adjustable. The rack box can be

positioned anywhere along the racking and torch removal and adjustment is simple.

• Quick clutch mechanism

• OSHA Safety Orange

• Ingress Protection (Sealed Unit) including Conformal Coated Circuit Boards

• Energy Efficient

• Universal Compatibility to all welding power sources and wire feeder

Torch holder memory for fast torch removal and accurate repositioning after cleaning : The

torch holder has been designed for quick and easy removal of the torch so that cleaning and

accurate repositioning of the welding torch in the optimal position is simple and consistent.

Compatible with all existing rigid track and the new semi rigid track sections

SPECIFICATIONS:

• Weight: 17 lb (7.7 kg)

• Speed Range: 2.5 - 83.1 cm/min (1 - 32.7 IPM)

• Racking Weight: 9 lb (4 kg)

• Power Requirements: 42 VAC, 115 VAC, 230 VAC Models available.

• Vertical Capacity: 56 lb (25.4 kg)

FEATURE DETAILS

DYNAMIC RACKING: Using a machined dovetail racking system and locking rack box, torch

positioning is versatile and adjustable. The rack box can be positioned anywhere along the

racking and torch removal and adjustment is simple.

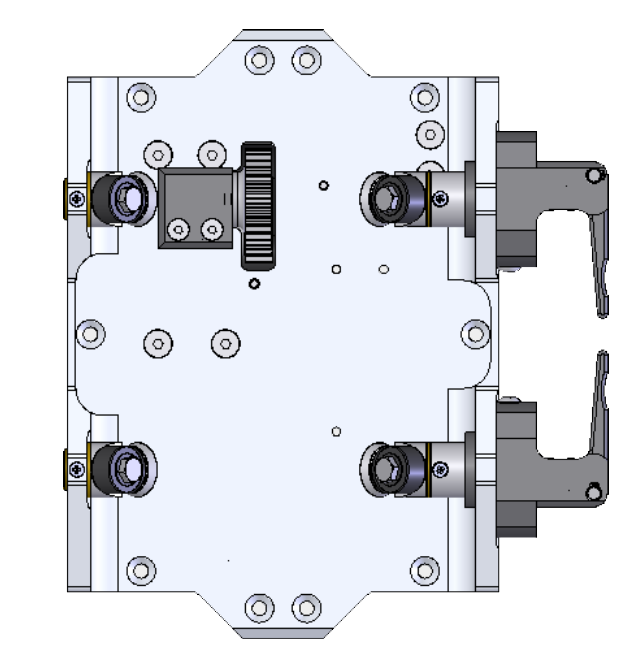

SELF-ALIGNING WHEELS: Self-aligning wheels means the carriage is mounted to the track

correctly and easily every time. This ensures smooth carriage motion and maximizes the life of

the track.

TORCH HOLDER MEMORY: The torch holder has been designed for quick and easy removal of

the torch so that cleaning and accurate repositioning of the welding torch in the optimal

position is simple and consistent.

PADDLE LOCKS: Quick installation paddle locks provide smooth transition of the self-aligning

wheels onto the track.

MACHINE UNDERCARRIAGE: Lightweight design engineered for optimal setup times utilizing

the self-aligning wheels and paddle lock technology.

SEMI RIDGID TRACK: Semi rigid track is made from precision extruded aluminium and a

securely affixed steel rack. The interchangeable end design enables fast accurate joining of the

track sections and provides smooth movement of the carriage along the track in both flat and

curved surfaces. Flexibility to a minimum of 24 ft. (7315.2 mm) ID/OD.

Specifications:

Input Supply : 42, 115 or 230

Model : KATŪ300 Welding Carriage | Linear Weld Oscillation