Safety Equipment Function Flash Back Arrestors

A flashback arrestor or flame arrestor is a device most commonly used in oxy-fuel welding and cutting to stop the flamefrom burning back up into the equipment and causing damage or explosions.

Flashback arrestors typically use a combination of methods to stop flashback. This is the type that is typically found in most workshops, homes and portable oxy-fuel kits as they work just as effectively with any orientation, need very little maintenance, and are often small and light enough to be installed between the torch and hoses.

They include:

Flame trap to cool the flame front. They are designed to allow free flow of gas through them but to take the heat out of the flame front to get it below the ignitiontemperature of the burning gas mixture. The most common types are:

» Sintered metal or ceramic.

» Layers of mesh.

» Ceramic beads.

Temperature-triggered valves to stop the gas flow completely. Because it relies on extracting heat from the flashback to stop it continuing, most arrestors have a temperature-controlled valve that will cut off the gas flow when the unit reaches around 90°C, until either the unit cools (if the unit is automatic) or the reset button is pressed (if the unit is manual).

A check valve that closes due to the back pressure.

» When a flammable mixture of fuel gas and air or oxygen is present in a gas line upstream of a welding or cutting blowpipe, flame can flash back into the gas line, and there is the possibility of a serious accident.

» A flame or flashback arrestor is a safety device designed to stop a flame in its tracks. It is therefore used to prevent flashback into cylinders or pipework.

» A flashback arrestor should not be confused with a non-return valve, which has no particular flame stopping properties. A non-return valve can reduce the probability of a flashback, as it serves to prevent reverse flow of oxygen into fuel lines and fuel into oxygen lines.

» The flame arrestor usually contains an element which may consist of narrow passages through a wire mesh or metal foam. When a flame enters the element, it is quickly cooled by the cold surface of the element and the flame is extinguished. The flame arrestor may contain a pressure or temperature actuated cut-off valve, and may then be known as a flashback arrestor.

» It is strongly recommended that arrestors with cut-off valves are fitted to the pressure regulator outlet of all acetylene cylinders and acetylene distribution systems. It is highly advisable to fit them to the oxygen outlet, and other fuel gas outlets. They can be fitted to the blowpipe, but this offers no protection from a fire arising from a leaking hose.

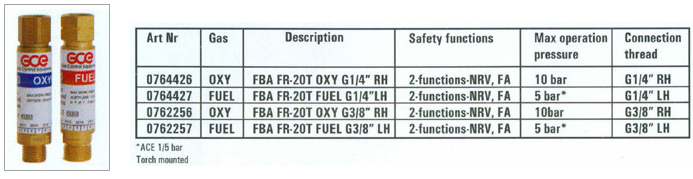

FR20T - 2 FUNCTION FLASH BACK ARRESTORS

FR20 is robust but lightweight torch flashback arrestor specially designed for torch fitting. Its all-brass design and high-grade soft sealing elements makes FR20 fully compatible with all common technical gases.

The unit incorporates the following features :

* FA SINTERED FLASH ARRESTOR element to quench a flashback.

* NV NON-RETURN VALVE to revent reverse flow of gases.

High Capacity sintered metal filter prevents foreugn matter entering the unit but quarantees capacity enough for all manual and medium-duty machine cutting applications. All FR20 flashback arrestors conform to EN 730

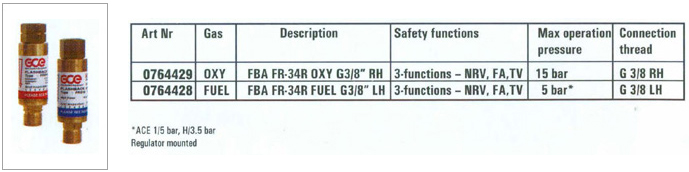

FR34R - 3 FUNCTION FLASHBACK ARRESTORS

The FR34 flashback arrestors are basic models of 3-function FBA designed to be mounted on the regulator side. Flow capacity of FR34 is sufficient for a whole range of manula cutting or welding applications and even for basic machine cutting up to 200mm. these arrestors fully comply with EN730 and ISO5175. FR34 offers three safety functions.

* FA Sintered flame arresting element.

* NV Non return valve to prevent reverse flow of gases.

* TV thermal trip device, activated by heat to permanently cut off gas supply.

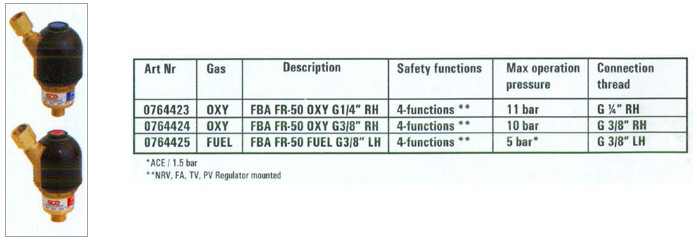

FR50 - 4 FUNCTION HIGH FLOW FLASHBACK ARRESTORS

A regulator mounted safety device suitable for all welding and cutting operations, fully complying with EN730, this lift to rest" unit incorporates the following features. FA Sintered flame arresting element.

* NV Non return valve to prevent reverse flow of gases.

* PV Pressure trip device, activated by pressure wave accompanying a flashback.

* TV thermal trip device, activated by heat to permanently cut off the gas supply.

* SI Status indicator shows green when unit is redy for use. In the event of flashback the item can be reset by lifting and releasing the bonnet.