GULLCOŪ KATŪ200

GULLCOŪ KATŪ200

Mehta Sanghvi & Co is the "Authorised Channel Partner for Gullco International"

KATŪ 200 rough and reliable carriages can be used to

automatize a single/multiple arc

welding or cutting operation(s) to enhance the grade or productivity.

The Gullco Rigid > KATŪ 200 welding carriage is used universally to automatize a broad range

of welding and cutting operations. KATŪ 200 WELDING AND CUTTING AUTOMATION

CARRIAGE - RIGID TRACK is a sturdy, reliable consistent welding and cutting travel carriage

which is designed for use on rigid track which facilitates it to function along any flat surface.

The rigid track can be used in straight portions or be formed for use on bended surfaces.

Cutting torches or the Welding guns boarded on the KATŪ200 carriage proceed along track at

accurately regulated speeds along the desired path in further or backward direction. Gullco's

Rigid KATŪ200 carriage facilitates cutting torches or the welding guns to function with

accurate speed from the beginning till end despite the number of passes or the work pieces

involved. Efficiency, Quality improvements and repeatability of the process can be achieved

by accepting this automation and which also eliminates Poor accessibility and inconsistency

of workmanship.

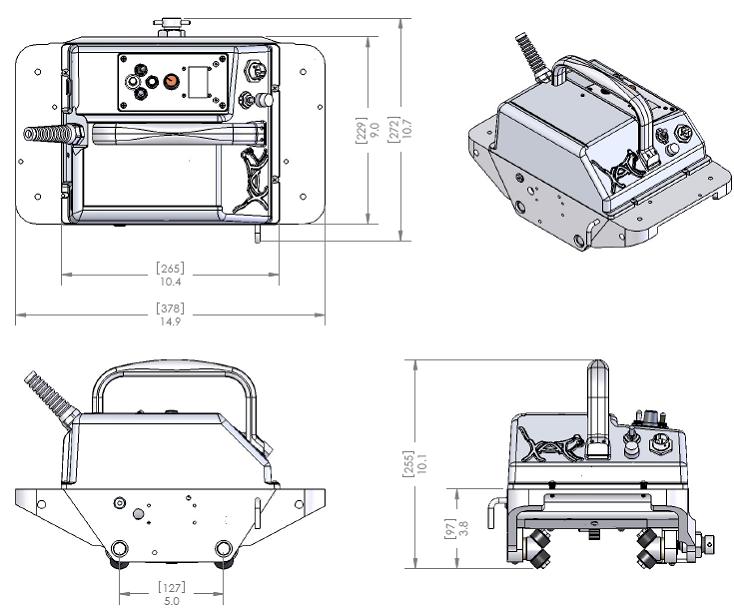

KATŪ 200 WELDING AND CUTTING AUTOMATION CARRIAGE - RIGID Track unit is designed for

functioning on smooth or undulated surfaces as this track can be used in vertical sections or

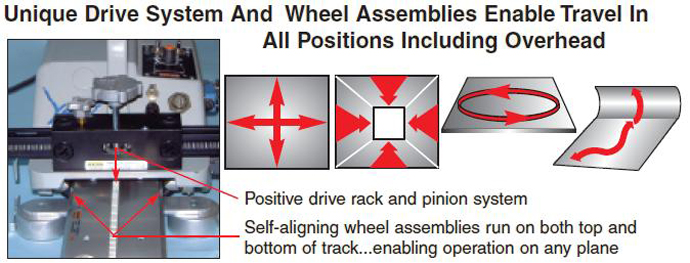

organized to comply the contour of the workpiece. The self-adjusting wheel method of the

carriage holds the top and bottom of the track, allowing it to move on any surface. The

modifiable wheel assembly holds the carriage snug to the track, to allow easy mounting and

also should be able to remove from the track at any point. The positive drive of the KATŪ200

is acquired from a peerless designed rack and pinion method, driven by a low voltage

permanent magnet motor and gear-head power unit assembly.

Features:

• Welding Carriage

• Programmable

• Low Voltage

• All Position

• Variable Speed