Plasma Cutting Inverter Cut Fire 100i

Technical Data

| Mains voltage | 3 x 400 V, 50 Hz |

| Max. Connecting load | 16.6 kVA |

| Fuse, slow | 25 A |

| Cutting current | 20 – 100 A |

| Duty cycle | 100 % |

| Cutting Range -Recommended -Maximum -piercing |

20mm 30mm 20mm |

| Plasma gas | Air |

| Dimensions (L x W x H) | 710 x 280 x 590 mm |

| Weight | 50 kg |

Plasma Cutting Inverter CutFire 100i

»

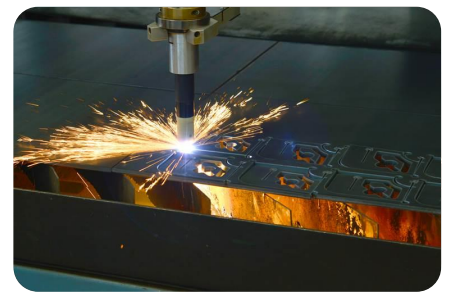

Integration in CNC-guiding systems or other mechanical guiding equipment

» Digital display of cutting current with set point pre-adjustment, display for operating readiness, plasma arc “ON” and cumulative error

» Stepless adjustment of cutting current

» Emergency stop button

» CNC-Interface (X102)

» Remote control FB 1

NEW: Plasma Machine Torch Flash 101*

» New consumables

» High cutting speeds

» Swirl gas Technology

» Safe piercing performance

» Increased lifetime of consumables

» Electrical height sensing contact**

NEW: Plasma Machine Torch Flash 101*

» Piercing up to 20 mm**

» Fine cutting from 3 mm

» Bevel cutting up to 30°

» Marking with 20 A

| Extract Cutting Chart Mild Steel | |||

| mm | A | Quality mm/min | Maximum mm/min |

| 2 | 45 | 4.200 | 6.000 |

| 3 | 45 | 2.800 | 3.500 |

| 4 | 45 | 1.900 | 2.300 |

| 4 | 65 | 4.400 | 5.500 |

| 6 | 65 | 2.850 | 3.700 |

| 10 | 65 | 1.100 | 2.000 |

| 8 | 100 | 3.000 | 4.00 |

| 10 | 100 | 2.400 | 3.350 |

| 15 | 100 | 1.200 | 1.800 |

| 20 | 100 | 750 | 1.100 |

| 25 | 100 | 500 | 700 |

| 30 | 100 | 200 | 520 |

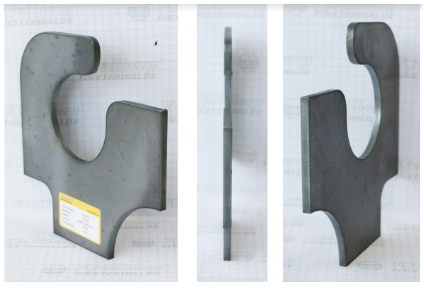

Cutting Sample 4 mm Mild Steel

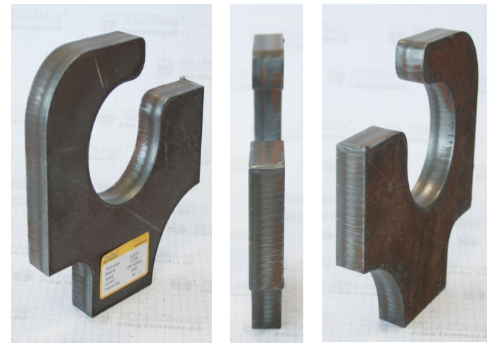

Cutting Sample 10 mm Mild Steel

Cutting Sample 16 mm Mild Steel

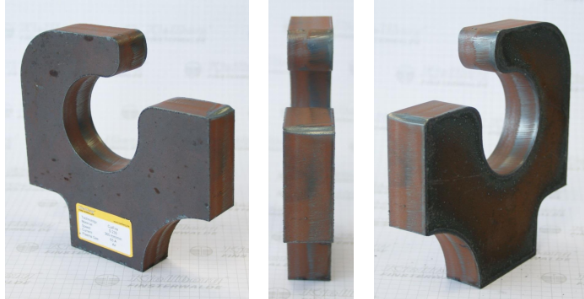

Cutting Sample 20 mm Mild Steel